Learning to Thrive as a Bladesmith: Nigara Uchihamono Tanzosho

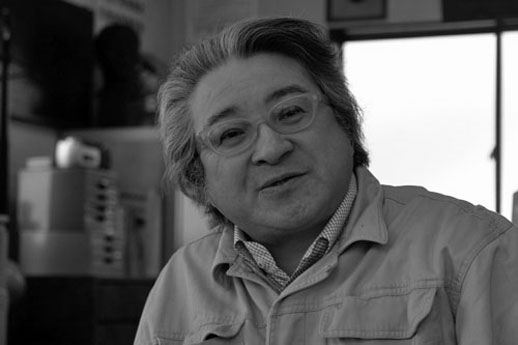

There’s a neighborhood in the city of Hirosaki, Aomori prefecture called Kajimachi. Kinzoku means “metal,” and this neighborhood lives up to its name. In the early days of the Edo period, Hirosaki was a castle town, and they say there were over one hundred forges based there. Tsugaru blades have their origin in this long, proud history. This week, we spoke with a man named Toshihisa Yoshizawa at a blade forge called Nigara Uchihamono Tanzosho about his reluctant entry and subsequent successful career in the bladesmithing industry. He’s participating in the local JAPAN BRAND project, Joppari Kanuchi.

Interview by Takafumi Suzuki. Translation by Claire Tanaka

Tell me, what are some of the unique features of Tsugaru blades?

Aomori is famous for apples. One thing that is very important for apple growers is to have a good pair of pruning shears. Pruning shears made in Tsugaru have become the standard in the orchard industry.

I see. They’re so highly rated that they have been chosen for the nationwide standard!

As you may know, the environment in Aomori is very harsh, and we grow apples under these difficult conditions. There are as many farmers growing apples here as there are stars in the sky. In response to requests from these people, over the years the pruning shears have gotten more and more refined, until now they are in their present superior form. It’s only natural that they would be of the highest quality.

What are the unique features of these nationally respected Tsugaru pruning shears?

The apple is a member of the rose family and the wood of the tree is very hard. Not only that, but the branches have to be pruned during the colder months. In other words, from the point of view of the pruner, if the shears don’t cut well, they aren’t any good at all. I think that’s a big reason why the blacksmiths of Tsugaru worked so hard to develop the shears. These days, I hear they’re also the chosen pruning shears of cherry blossom tree surgeons.

I see. Now, what are your main products here at Nigara Uchihamono Tanzosho?

Basically, we make kitchen knives, regular knives, and hatchets. Tsugaru blades have their origin in a swordsmith that was based here over one thousand years ago. Here at the forge, we’re basically carrying on the tradition started by that swordsmith.

You’re participating in the local JAPAN BRAND project, Joppari Kanuchi. Are you making kitchen knives, regular knives, and hatchets for that too?

Yes, that’s right. The regular knives we make can be used for grafting apple trees and crafting things out of bamboo; they have a lot of different uses. We have a whole range of kitchen knives, including carving knives, sashimi knives, and meat cleavers. I’m hoping that this project will serve as a way to encourage young people and potential business successors to gather in Tsugaru and revitalize the region. We’ve had a lot of coverage in magazines, on television, and on the internet, which has brought a lot of attention to our region. When I think about that, I realise what a large impact this project has had.

The surface pattern on your blades is very beautiful.

We use several different kinds of steel piled together and welded into a steel laminate which causes the pattern you see. There are never any two the same. The cutting edge too is made in the swordsmithing style, and it’s very sharp. I noticed the beauty of that pattern and I’ve been making art pieces. (laughs)

Is that so! But, if you take it so far as to make art from your materials, you must really be connected to your work as a craftsman.

No, actually I hated manufacturing when I started, and even now I’m not all that fond of it. When I started my apprenticeship, I made a lot of mistakes and I felt I couldn’t do anything right. Every time I stepped into the workshop I was scolded. I hated working in such a high-pressure environment.

That’s surprising to hear. Mr Yoshizawa, when did you start learning to become a blacksmith?

Actually, when I was a child, my first year in junior high, my father and the Nigara family decided that I’d be the one to take over this workshop. So even during summer holidays when I was in junior high, I had to come and help out here. The reason I wound up in that position was because my parents were teachers at the junior high and they had a strong belief in doing something for the community. The Nigara family were having trouble finding someone to take over their business, so they basically handed me over to them.

That’s a huge decision for someone to make on your behalf. But even though you started at such a young age, you say it was hard for you to learn all the tricks of the trade?

I think I must be the least coordinated person in the world. I went to an industrial high school, but I just didn’t feel it suited my personality. But it’s a funny thing, I do enjoy making things now.

When I look at how beautiful the Nigara knives are, I just want to own one. I have a really hard time believing that you were ever uncoordinated.

I started to enjoy my work when I went out to the sales floor and communicated directly with my customers.

Why do you think that is?

Once I could hear the customers’ voices for myself, I realised that what was going on in the workshop and what was being said on the sales floor were different. And I began to think about what to do to fill in that gap. In other words, talking to the customers helped me think about how to make knives that would make the customers happy, knives that would sell. Just because you’ve got a talented craftsman putting his heart into his work doesn’t necessarily mean that he’s making something that will please the customers. Once I realized that, my job got a lot more interesting.

Your slight dislike for your work might have helped you arrive at that conclusion. A naturally gifted craftsman might be too high on his own talents to think of how the buying end feels about things. They’d just think, “As long as I work hard, it’s gotta sell.”

You could be right. The way I see it, that old cliche, “Silence is golden” is a farce. Craftsmen have to be good with words, and they’ve got to know a lot about society. Just being shy, complaining only when we drink, being pessimistic about traditional industry, if we’re like that, we’re going to sink our own ships. That’s why I have to work hard at what I do so that I can buy a nice car like a Porche and build a big house. If I don’t make that much, it’s no good. If you work with a mentality like mine, even an uncoordinated guy like me can enjoy traditional manufacturing.

You’re looking at it from a new angle. Now, finally, tell me what you envision for yourself and your work.

Tsugaru blades have their origin with swordsmithing, so I’ve been thinking I’d like to get my swordsmithing qualifications. Now, I don’t like to be interrupted by anyone when I’m working in the forge. When I think about how I can concentrate now, it’s hard to believe I ever hated this work. (laughs)

A Word from a Regional Product Participant

Hirosaki City Chamber of Commerce and Industry

Japan Brand Project Administrator

Our Joppari Kanuchi project was formed by the chamber, local blacksmiths, and members of an executive committee. Our goal is to communicate our traditional skills to a new generation. Joppari is a word in the local Tsugaru dialect which means “a stubborn person.” This is an important word in expressing the character of the people of Tsugaru (the old name for the region of Aomori which includes Hirosaki City.) Kanuchi means “beating metal,” in otherwords, a blacksmith. Tsugaru is home to a number of ancient forge ruins, and they say the region was once a kingdom that flourished because of its superior metalworking technology. It is said that the technology was brought to the area from around tenth century via sea routes in the Sea of Japan. We feel we have a duty to continue this ancient local metalworking culture and bring it to the next generation, while also using it as an opportunity to revitalize our communities. Thanks to the JAPAN BRAND project, our efforts have been taken up by the media, and we were able to participate in a Paris trade show and find an agent to represent our products. Our reputation overseas seems to be growing. For our next challenge, we’re hoping to make some collaborative products with other local traditional crafts, such as kogin-zashi needlework, and lacquerware.

Japan Brand

Japan Brand